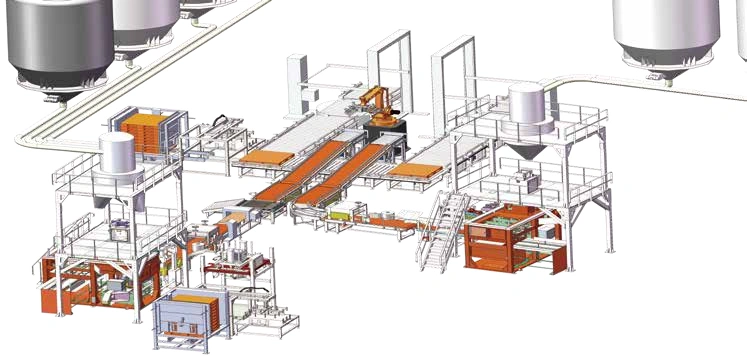

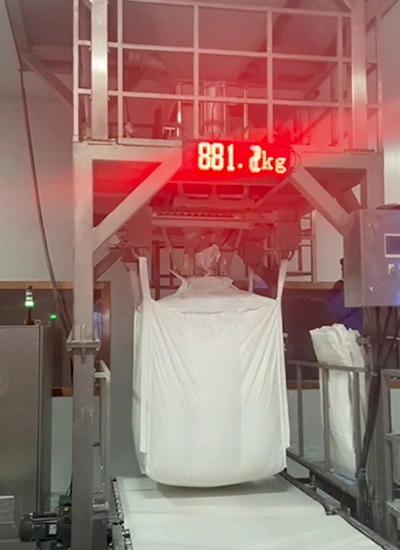

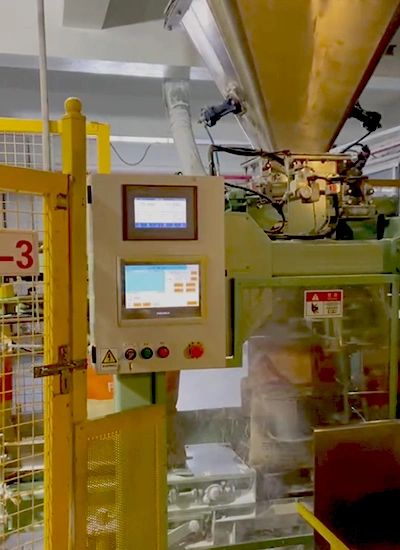

Bagging and Palletizing System

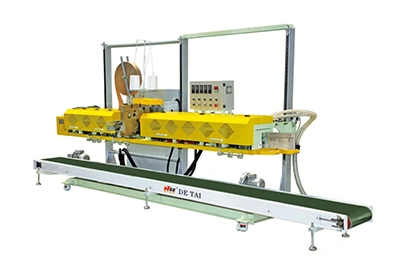

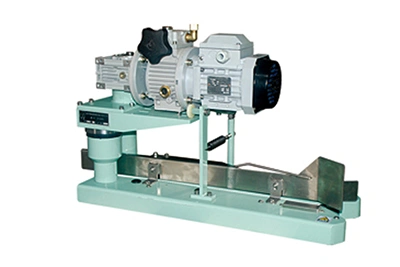

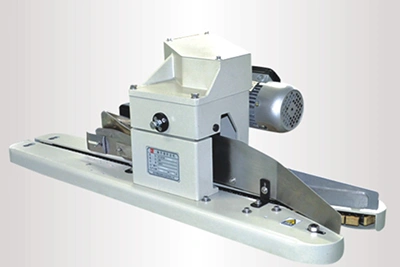

Detai specializes in engineering and manufacturing integrated bagging and palletizing systems, including open-mouth bagging machines, bag sealing machines, bag sewing machines, bagging scales, and automated bag palletizing systems.