Food Packaging

- Home

- Customer Cases

- Food Packaging

The food packaging industry spans a wide range of products and demands precise, efficient, and adaptable handling across every stage, including bagging, sealing, palletizing and depalletizing of different food items. A food producer selected our dual-station FIBC filling system for packaging glucose and valine powder. This project required strict compliance with food-grade hygiene standards, stable sealing performance, and reliable dust control.

The project called for a system designed for food-grade operation. All contact surfaces required polished 304 stainless steel, and both soft connections and conveyor belts needed to meet food-grade material standards. The conveyor chain and rollers had to balance mechanical strength with corrosion resistance. The electrical system demanded an explosion-proof configuration, including certified motors and a capacitor-touch control panel. The production area also required a high-capacity dust-extraction setup with an airflow of at least 6000 m³/h, equipped with a recovery tray and explosion-relief outlet to maintain a clean and safe environment.

Detai supplied a system fully aligned with these requirements. All product-contact components were built from polished 304 stainless steel, and food-grade materials were used for soft connections and belts. BFM quick-release connectors were selected for safe and hygienic handling. The conveyor chain was nickel-plated carbon steel, while the rollers featured nickel-plated surfaces and chrome-plated internal shafts, ensuring both durability and corrosion resistance.

The electrical system followed a complete explosion-proof design, equipped with SEW explosion-proof motors and a capacitor-touch control interface. A high-efficiency dust-extraction system, also constructed in 304 stainless steel, delivered an airflow of ≥6000 m³/h and included both a recovery tray and an explosion-relief port. This configuration ensured a clean production area and full compliance with food-safety and explosion-protection standards.

From bagging to palletizing, we design and manufacture full packaging lines engineered to match your bulk materials, capacity needs, and plant layout.

From single units to complex multi-line projects, we create custom solutions to fit your needs.

Choosing the right open-mouth bagging machine depends on production scale, budget, and the level of automation required.

Learn MoreDetai provides heat sealing solutions for paper–plastic composite bags, aluminum-laminated woven bags, and multilayer film bags, supporting block-type and impulse sealing methods for bulk-material packaging.

Learn MoreBag sewing machines use mechanical drive components combined with pneumatic cylinders or electric control systems to stitch the mouth of filled packages.

Learn MoreOur palletizing line is designed for industrial bag-handling applications and integrates seamlessly with upstream equipment such as automatic bagging machines, weighing units ...

Learn More

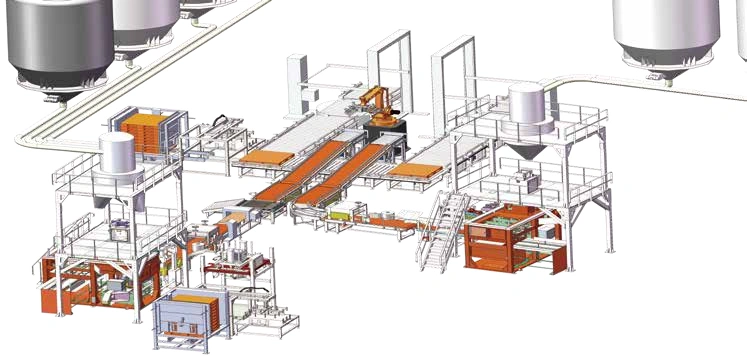

A complete bag packaging line brings together every stage of filling, sealing, inspection, and palletizing into one coordinated system. From bagging and conveying to load preparation for shipment, each module works in sequence to create a smooth, continuous workflow. The layout below reflects the standard configuration used across grain, chemical, fertilizer, and feed production environments to meet their demands for stable output and precise handling.

Learn More