Chemical Packaging

- Home

- Customer Cases

- Chemical Packaging

The chemical packaging industry handles a broad variety of powders and granules, each with its own flow characteristics, dust behavior, and safety requirements. Packaging lines in this sector need stable filling performance, reliable sealing, and smooth handling of different bag types to keep production efficient and consistent.

A PVC resin manufacturer selected our automatic bagging system for packaging PVC (polyvinyl chloride) granules. The solution combined a servo-driven dual gravity scale, transition hopper, 3CM-PS automatic open-mouth bagging machine, and GKS-13 paper bag heat-sealing and stitching unit. This configuration ensured high-speed operation, compatibility with the required bag types, and full alignment with the customer’s performance and material standards.

The packaging line needed to achieve an output of 800 bags per hour with a 25 kg filling weight. The specified bags were M-type multi-wall kraft paper sacks with a composite structure (three-in-one). The system also had to handle two empty bag sizes: 860 × 450 mm and 890 × 460 mm, and a filled bag dimension of 700 × 460 × 150 mm. All product-contact components were required to be stainless steel, while the remaining machine frame could be carbon steel. Fasteners such as screws and nuts needed to be stainless steel. Several electrical components had to be supplied in designated imported brands to ensure compatibility with the customer’s existing production environment.

A 3CM-PS automatic bagging machine with a capacity exceeding 800 bags per hour was configured for this project, fully matching the customer’s bag type and size specifications. All contact points were manufactured in 304 stainless steel, while the main frame used carbon steel for durability and structural integrity. This setup ensured hygienic handling of the material, stable filling performance, and reliable operation in line with the customer’s technical, structural, and integration requirements.

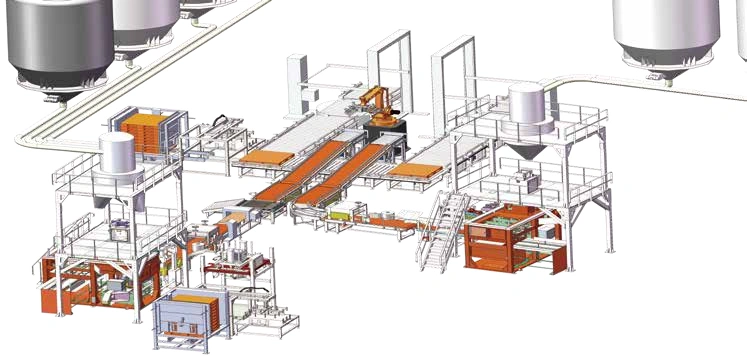

From bagging to palletizing, we design and manufacture full packaging lines engineered to match your bulk materials, capacity needs, and plant layout.

From single units to complex multi-line projects, we create custom solutions to fit your needs.

Choosing the right open-mouth bagging machine depends on production scale, budget, and the level of automation required.

Learn MoreDetai provides heat sealing solutions for paper–plastic composite bags, aluminum-laminated woven bags, and multilayer film bags, supporting block-type and impulse sealing methods for bulk-material packaging.

Learn MoreBag sewing machines use mechanical drive components combined with pneumatic cylinders or electric control systems to stitch the mouth of filled packages.

Learn MoreOur palletizing line is designed for industrial bag-handling applications and integrates seamlessly with upstream equipment such as automatic bagging machines, weighing units ...

Learn More

A complete bag packaging line brings together every stage of filling, sealing, inspection, and palletizing into one coordinated system. From bagging and conveying to load preparation for shipment, each module works in sequence to create a smooth, continuous workflow. The layout below reflects the standard configuration used across grain, chemical, fertilizer, and feed production environments to meet their demands for stable output and precise handling.

Learn More