Heated-Bar Bag Sealing Machine for Bagging & Palletizing System

- Home

- Bagging and Palletizing System

- Bag Sealing Machines

- Heated-Bar Bag Sealing Machine

- Paper Bag Heat Sealing and Stitching Machine

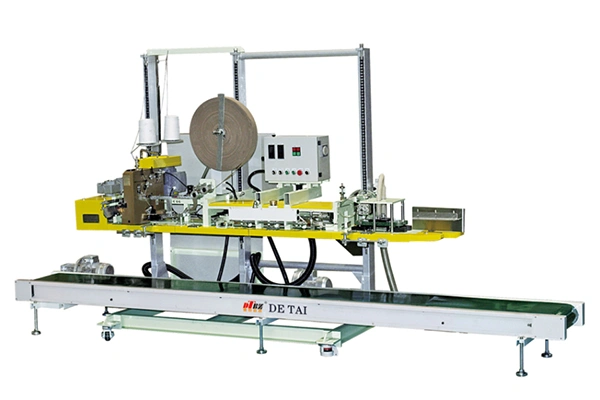

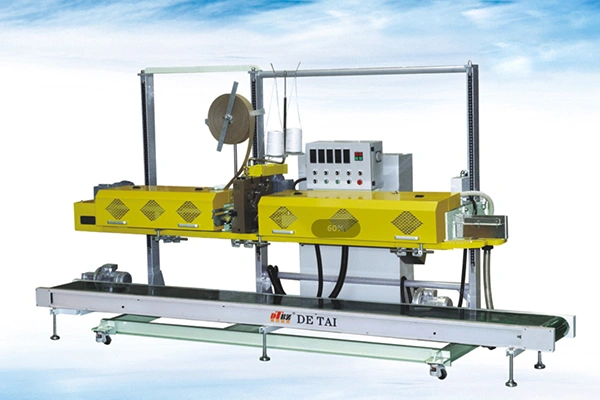

The paper bag heat stealing machine is designed for high-speed closing of multi-wall paper bags with internal PE liners. It supports sealing speeds of 7–10 m/min and a sealing height range of 800–1700 mm, making it suitable for a wide variety of paper-bag packaging lines.

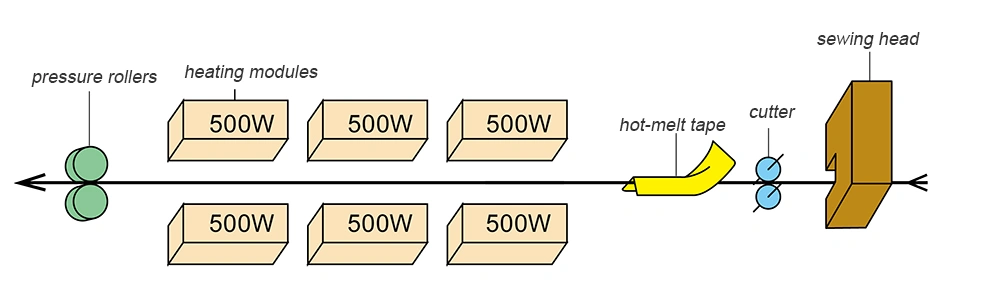

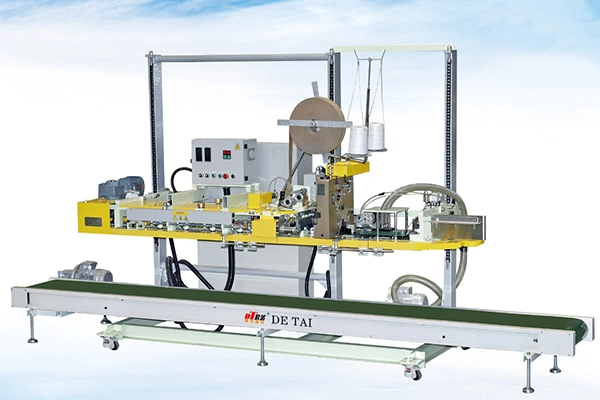

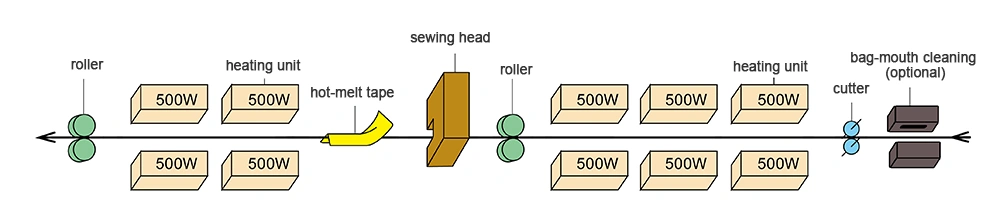

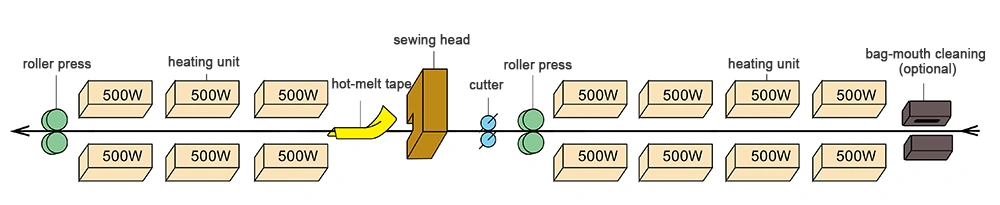

Sewing machine: stitches the outer paper bag → Cutter: trims the bag top (optional) → Hot-melt tape application (3 heated-bar modules) → Pressure rollers: press and bond the tape

| Model | GKS-13 |

| Sealing speed | 7–12m/min |

| Heating power | 0.5kW×6 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Total power | 4kW |

| Machine dimensions (L×W×H) | 2250×1090×2052mm |

| Machine weight | Approx. 490kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 3-layer flat-top paper bags (inner PE liner heat sealing, outer hot-melt tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

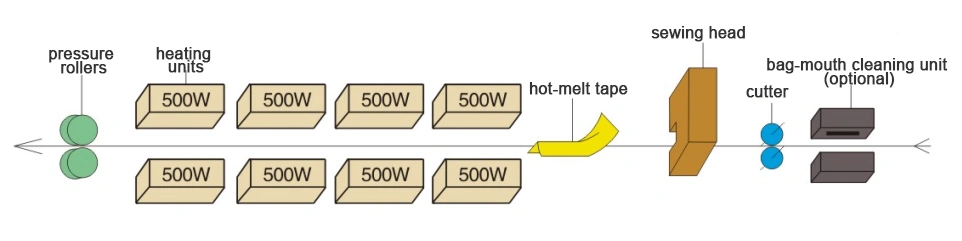

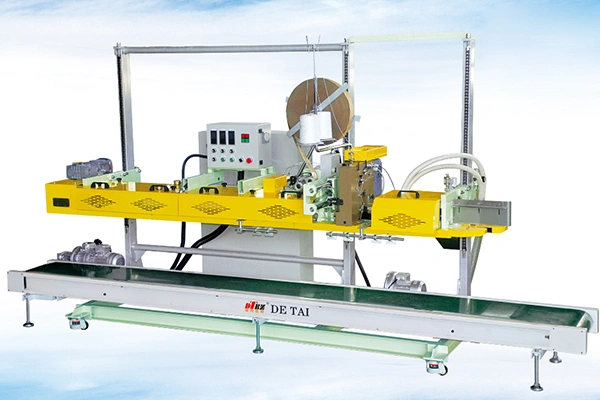

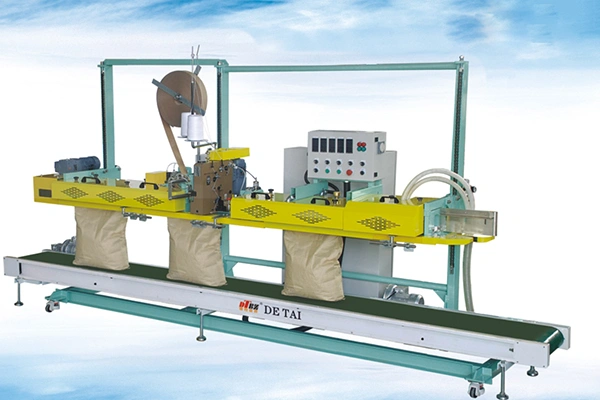

Bag mouth cleaning (optional) → Cutter: trimming the bag mouth → Sewing machine: stitching the outer paper bag → Hot-melt tape application → Inner bag heat sealing (4 heated-bar assemblies) → Pressure rollers for compression

| Model | GKS-14D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×8 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW |

| Total power | 5.5kW |

| Machine dimensions (L×W×H) | 2850×1090×2052mm |

| Machine weight | Approx. 580kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 4-layer flat-top paper bags (inner PE liner heat sealing, outer hot-melt tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

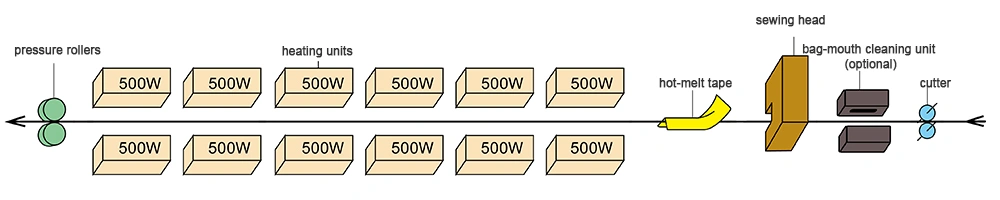

Bag-mouth cleaning (optional) → cutter: trims the bag mouth → sewing machine: stitches the outer paper bag → hot-melt tape → inner-liner heat sealing (6 sets of heated bars) → pressure rollers for sealing

| Model | GKS-16D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×12 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW (optional) |

| Total power | 8kW |

| Machine dimensions (L×W×H) | 3250×1090×2052mm |

| Machine weight | Approx. 800kg |

| Sewing head model | GS-11 |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 6-layer flat-top paper bags or 3-layer M-gusset bags (inner PE liner heat sealing, outer hot-melt tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

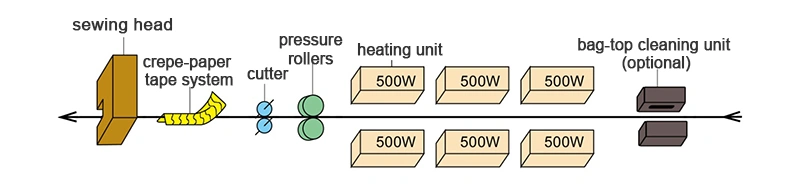

Bag-top cleaning (optional) → Inner-liner sealing (4 heating-block groups) → Pressure rollers press and bond the seam → Cutter: trims the bag top → Crepe-paper tape application → Sewing head: stitches the outer bag

| Model | GKS-23D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×6 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW (optional) |

| Total power | 4.5kW |

| Machine dimensions (L×W×H) | 2850×1090×2052mm |

| Machine weight | Approx. 570kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 3-layer flat-top paper bags (inner PE liner heat sealing, outer crepe-paper tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

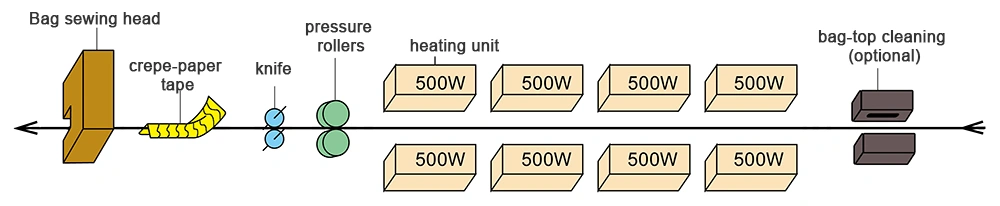

Bag-top cleaning (optional) → Inner bag heat sealing (3 heating-bar groups + 1 cooling bar) → Pressure-roller sealing → Knife: bag-top trimming → Crepe-paper tape → Bag sewing machine: outer bag stitching

| Model | GKS-24D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×8 |

| Sealing power | 0.4kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW (optional) |

| Total power | 5.5kW |

| Machine dimensions (L×W×H) | 3000×1090×2052mm |

| Machine weight | Approx. 620kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 4-layer flat-top paper bags (inner PE liner heat sealing, outer crepe-paper tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Bag-mouth cleaning (optional) → Cutter: bag-mouth trimming → Inner-bag heat sealing (3 heating-bar units) → Roller pressing → Sewing machine: outer bag stitching → Hot-melt tape → Heat sealing (2 heating-bar units) → Roller pressing

| Model | GKS-232D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×10 |

| Sealing power | 0.55kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW |

| Total power | 6.5kW |

| Machine dimensions (L×W×H) | 3300×1090×2052mm |

| Machine weight | Approx. 800kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 3-layer flat-top paper bags (inner PE liner heat sealing, outer hot-melt tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Bag-mouth cleaning (optional) → Inner bag heat sealing (4 heating-bar groups) → Roller pressing → Cutter: bag-mouth trimming → Sewing machine: outer bag stitching → Hot-melt tape → Heat sealing (3 heating-bar groups) → Roller pressing

| Model | GKS-243D |

| Sealing speed | 7–10m/min |

| Heating power | 0.5kW×14 |

| Sealing power | 0.55kW |

| Sewing power | 0.4kW |

| Bag mouth cleaning power | 0.55kW (optional) |

| Total power | 8.5kW |

| Machine dimensions (L×W×H) | 3670×1090×2052mm |

| Machine weight | Approx. 850kg |

| Sewing head model | GS-7C |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | 4-layer flat-top paper bags (inner PE liner heat sealing, outer hot-melt tape) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

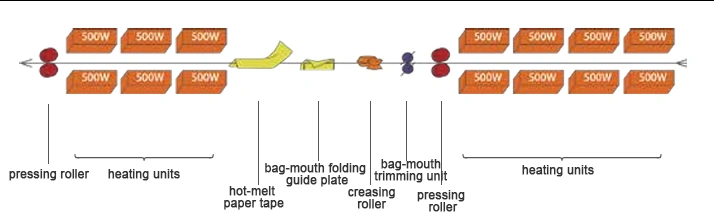

Bag-mouth cleaning → Inner PE bag heat sealing (4 groups of heated bars) → PE inner bag pressing roller → Bag-mouth trimming → Bag-mouth folding and creasing roller → Bag-mouth folding → Hot-melt paper tape application → Hot-melt paper tape sealing (3 groups of heated bars) → Pressing roller compaction → Bag-mouth folding and hot-melt tape sealing completed

| Model | GKS-324D |

| Sealing speed | 7–10m/min (fatory setting 10m/min) |

| Sealing height (from floor) | 800–1700mm |

| Sealing temperature | 0 to 400℃ |

| Drive motor power | 0.75kW |

| Heating power | 0.5kW×12 |

| Total power | 8kW |

| Machine dimensions (L×W×H) | 3700×1020×2050mm |

| Bag-mouth clearance | ≥250mm (distance from product level to bag mouth) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn More