Bag Closing Pedestal for Bagging & Palletizing System

- Home

- Bagging and Palletizing System

- Bag Sealing Machines

- Bag Closing Pedestal

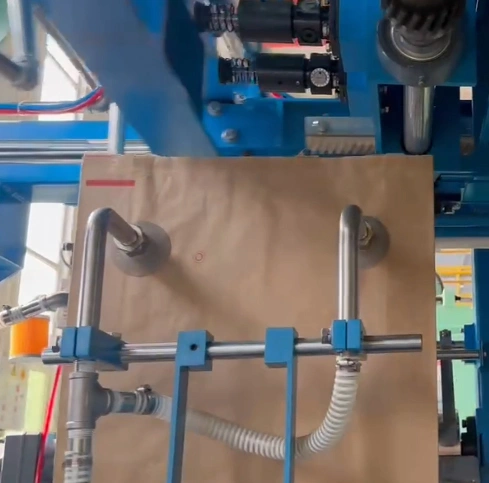

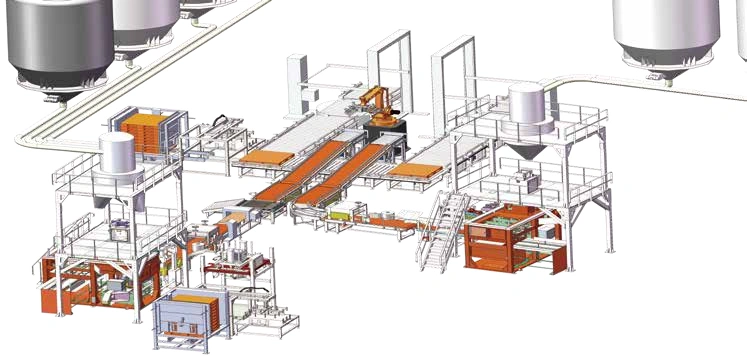

The bag closing pedestal is built from a column, base, lifting frame, electrical cabinet, and operation panel. It can be used as a standalone unit for small-scale bag closing needs, or integrated with conveyors and automatic open-mouth bagging machines to create a combined system for bag feeding, filling, folding, sewing, sealing, labeling, and conveying. This flexibility allows the pedestal to support both small-batch production and higher-volume packaging lines.

The A1 pedestal is compatible with multiple sewing machine models, including GS-7, GS-9, GS-11, and GK35. It can be paired with various bag-top folding devices such as GP4900, GM4900-3, GP1860, and GP6000 to support bag-top trimming and improve leak prevention. It is equipped with a dual-inverter or triple-inverter control cabinet, suitable for multi-equipment linkage and operating conditions that involve dynamic changes.

| Sewing height range | 850–1500mm |

| Motor speed | 1390rpm |

| Motor power | 0.55kW |

| Conveyor speed | 12m/min |

| Operating temperature | 10°C to 40°C |

| Air pressure | 0.4MPa |

| Air consumption | 3.5NL/min |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

The A2 pedestal features a more compact structure, ideal for production sites with limited space. Compatible sewing machines mainly include the GS-9 and GK35 series, meeting the basic production needs of most users. It is equipped with an LZB control cabinet (can be paired with a brake motor), enabling precise coordination and energy-efficient operation.

| Sewing height range | 770–1320mm |

| Motor speed | 1390rpm |

| Motor power | 0.55kW |

| Conveyor speed | 12m/min |

| Operating temperature | 10°C to 40°C |

| Air pressure | 0.4MPa |

| Air consumption | 3.5NL/min |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

The A3 pedestal provides enhanced load-bearing capacity and is primarily used with the GS-9 and GK35 bag sewing machines for more stable integrated operation. It can also be paired with our label applicator. The pedestal is equipped with dual-inverter or triple-inverter control cabinets, allowing it to adapt flexibly to changing operating conditions and integrate smoothly with multiple pieces of equipment.

| Sewing height range | 850–1500mm |

| Motor speed | 1390rpm |

| Motor power | 0.55kW |

| Conveyor speed | 12m/min |

| Operating temperature | 10°C to 40°C |

| Air pressure | 0.4MPa |

| Air consumption | 3.5NL/min |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn MoreThe A1 pedestal is compatible with sewing machine models such as GS-7, GS-9, GS-11, and GK35. It can also be paired with bag-folding devices including GP4900, GM4900-3, GP1860, and GP6000 to support bag-top trimming and material-leak prevention requirements.

The GL-3 conveyor can be combined with Detai’s automatic open-mouth bagging machines and pedestal systems to achieve an integrated workflow that includes bag placing, filling, sewing, and conveying—ideal for medium- and high-throughput production lines.

The pedestal is equipped with hand-wheel mechanisms at the ends of the lead screw and top screw. Operators can easily adjust the height of the sewing machine or bag-folding device by turning the hand wheel—no specialized tools needed.

The GL-3 conveyor features adjustable pedestals with a standard height-adjustment range of 100–150 mm, and custom ranges are also available. The adjustment process is simple and does not require complex operations.