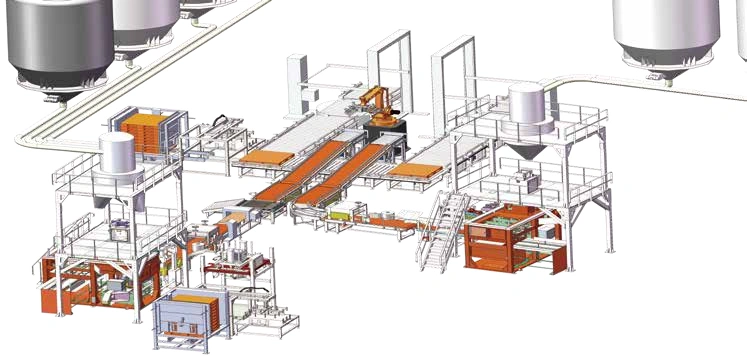

Heated-Bar Bag Sealing Machine for Bagging & Palletizing System

- Home

- Bagging and Palletizing System

- Bag Sealing Machines

- Heated-Bar Bag Sealing Machine

- PP/PE Bag Heat Sealing Machine

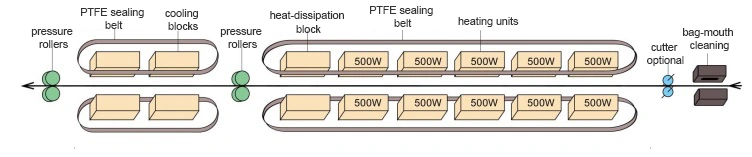

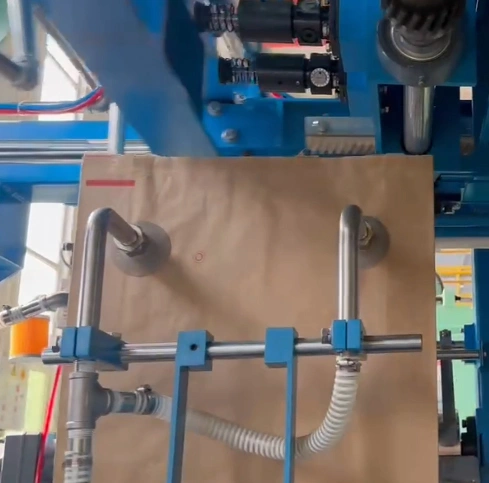

The heat-sealing machines are designed for closing heavy-duty PE and PP bags, as well as paper–plastic and aluminum-laminated composite bags. The system uses a TEFLON (PTFE) sealing belt to prevent sticking during the sealing process and to maintain a clean, uniform seal. This configuration ensures stable sealing quality even with thicker multi-layer materials, making it suitable for demanding industrial applications where strength and reliability matter.

Bag-top cleaning → Optional trimming knife to prepare and straighten the bag mouth → plastic-bag heat sealing (three heating-block groups + one cooling block; the PTFE sealing belt keeps the heating block from contacting the bag directly, preventing sticking and protecting the outer surface) → pressure rollers for sealing compression → plastic-bag cooling (two cooling-block groups) → knurling by pressure rollers

| Model | FBH-32D |

| Sealing speed | 7–12m/min |

| Heating power | 0.5kW×6 |

| Sealing power | 0.55kW |

| Bag mouth cleaning power | 1.6kW |

| Total power | 5.15kW |

| Machine dimensions (L×W×H) | 2830×950×1780mm |

| Machine weight | Approx. 300kg |

| Sealing height (from floor) | 750–1450mm |

| Sealing width | 8–10mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Polyethylene (PE) film, Polypropylene (PP) film |

| Applicable film thickness | ≤1.0mm |

| Bag-mouth clearance | ≥250mm (distance from product level to bag mouth) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Bag-mouth cleaning → Cutter: bag-mouth trimming (optional) → Plastic bag heat sealing (4 heating-block groups + 1 cooling-block group: the PTFE sealing belt prevents direct contact between the heating blocks and the bag surface to avoid sticking) → Pressure-roller sealing → Plastic bag cooling (2 cooling-block groups) → Embossing roller

| Model | FBH-42D |

| Sealing speed | 7–12m/min |

| Heating power | 0.5kW×8 |

| Sealing power | 0.55kW |

| Bag mouth cleaning power | 0.55kW |

| Total power | 5.5kW |

| Machine dimensions (L×W×H) | 3120×1020×2052mm |

| Machine weight | Approx. 350kg |

| Sealing height (from floor) | 800–1700mm |

| Sealing width | 8–10mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Polyethylene (PE) film, Polypropylene (PP) film |

| Applicable film thickness | ≤1.0mm |

| Bag-mouth clearance | ≥250mm (distance from product level to bag mouth after closing) |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

Bag mouth cleaning → Cutter: trimming the bag mouth (optional) → Plastic bag heat sealing (3/4/5 sets of heated bars + 1 set of cooling bars: the PTFE sealing belt prevents direct contact between the heated bars and the bag surface, avoiding adhesion and protecting the outer layer) → Roller pressing → Bag cooling (2 sets of cooling blocks) → Roller knurling

| Model | FBH-52D |

| Sealing speed | 7–12m/min |

| Heating power | 0.5kW×10 |

| Sealing power | 0.55kW |

| Bag mouth cleaning power | 1.5kW |

| Total power | 7.5kW |

| Machine dimensions (L×W×H) | 3305×1020×2052mm |

| Machine weight | Approx. 600kg |

| Sealing height (from floor) | 800–1700mm |

| Sealing width | 8–10mm |

| Sealing temperature | 0 to 400℃ |

| Applicable materials | Polyethylene (PE) film, Polypropylene (PP) film |

| Applicable film thickness | ≤1.0mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn More