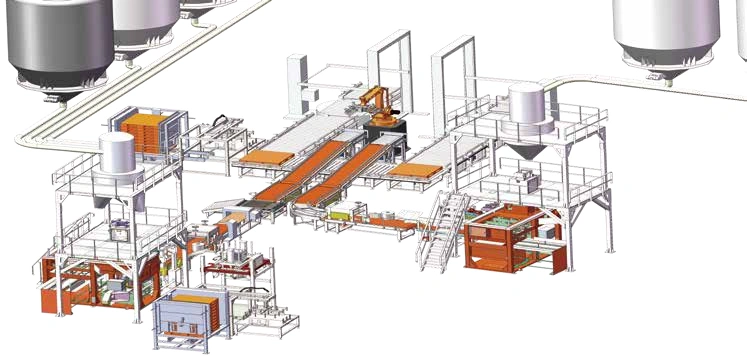

This belt-type folding device prepares the bag mouth before sewing by folding the upper edge into a clean, uniform shape. Once the fold is formed, downstream sewing systems can create a stronger and more secure closure. This greatly reduces issues such as bag leakage, loose stitching, or breakage during handling and transport. It is a reliable front-end component widely used on packaging lines in grain processing, chemicals, fertilizers, animal feed, and other industries where consistent sealing quality is essential.

Woven bags

Woven bags

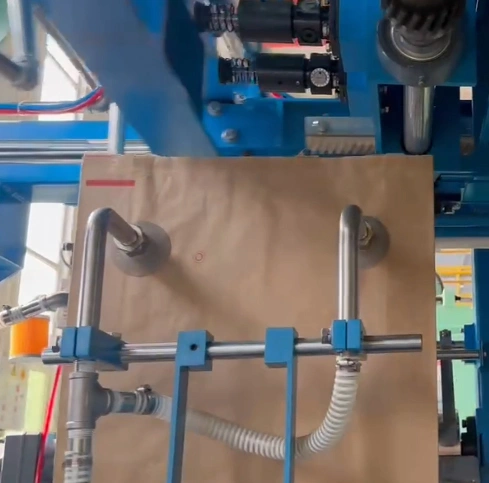

Paper–plastic laminated bags

Paper–plastic laminated bags

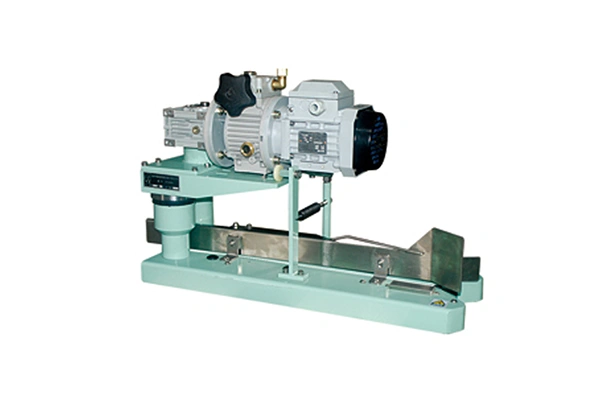

| Machine main material | Carbon steel or stainless steel (optional based on customer requirement) |

| Folding width | 35–50mm |

| Bag feeding speed | 5–12m/min |

| Applicable bag thickness | 4–6 layers of woven bags |

| Power supply | 380V/50Hz |

| Motor brand | SEW, NORD, Mitsubishi (customizable) |

| Motor power | 0.18kW / 0.2kW / 0.25kW |

| Machine weight | 32kg |

| Machine dimensions (L×W×H) | 710×240×370mm |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn More