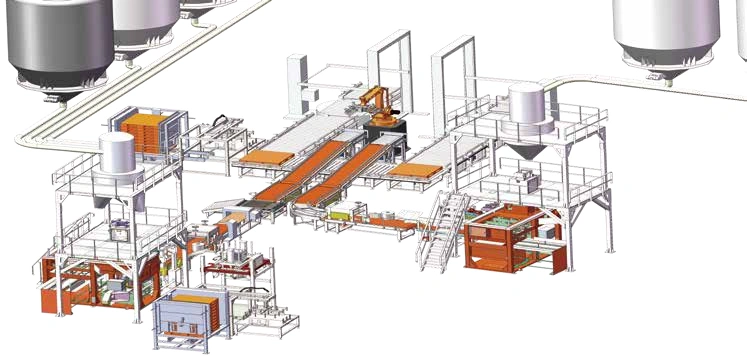

Bagging Scale for Bagging & Palletizing System

- Home

- Bagging and Palletizing System

- Bagging Scale

- Screw Feed Bagging Scale

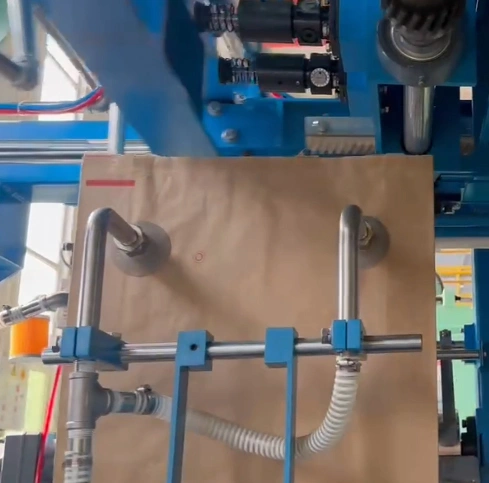

The screw feed bagging scale uses two motors to drive the screw for coarse and fine feeding, with a cut-off gate and frequency-controlled speed regulation. It is designed for powders and fine granular materials with moderate flowability, such as flour, milk powder, and powdered chemicals.

To maintain stable discharge, the outlet tube is equipped with a pneumatic vibration device to prevent bridging or adhesion, along with an adjustable air-return system to support clean, uninterrupted flow. A dust-extraction port is integrated into the system to improve workplace cleanliness and reduce airborne material during operation. The screw feeding scale uses a high-performance weighing controller and sensors to deliver a high level of automation. Coarse and fine feeding, bag clamping, and bag release are all managed automatically. The system can auto-tare and adjust errors during weighing, with adaptive optimization that fine-tunes control actions throughout the process. It provides gross weight, net weight, totalized weight, and bag count display, enabling automatic production data management. The controller can be connected to computers or printers for extended data integration.

| Feeder type | Weighing range | Max. capacity | Accuracy | Power | Power supply | Control voltage |

| Screw feeder (double hopper) | 20-50 | 13 | ≤±0.2%FS | 8.4kW | AC3PH380V 50Hz | DC 24V |

| 5-20 | 13 | ≤±30g | 6.4kW | |||

| Screw feeder (single hopper) | 20-50 | 8 | ≤±0.2%FS | 4.4kW | AC 220V 50Hz | DC 24V |

| 5-20 | 7 | ≤±30g | 3.2kW | |||

| Screw feeder (without hopper) | 20-50 | 5 | ≤±0.2%FS | 4.4kW | AC 220V 50Hz | DC 24V |

| 5-20 | 5 | ≤±30g | 3.2kW |

1. Feeder type depends on capacity, material characteristics, accuracy and budget requirements:

2. Maximum capacity values are based on packaging corn or corn flour under specified conditions.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn More