Bagging Scale for Bagging & Palletizing System

- Home

- Bagging and Palletizing System

- Bagging Scale

- Gravity Feed Bagging Scale

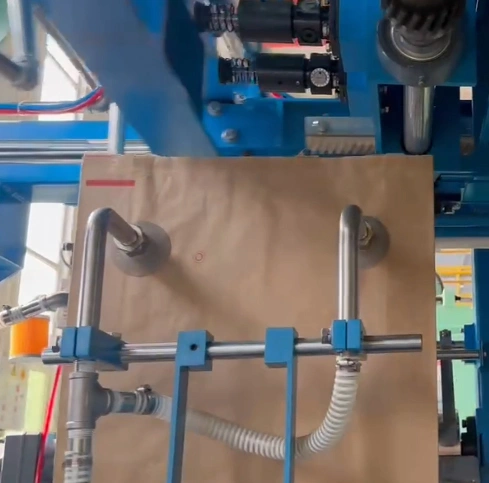

The servo gravity feed bagging scale uses a servo-driven feeding system instead of the traditional dual-cylinder setup. This upgrade delivers faster response, steadier operation, and higher weighing accuracy while eliminating fluctuations caused by air-pressure instability.

The weighing structure adopts three high-precision load cells arranged at equal angles around the scale’s center of gravity. This layout prevents uneven force distribution which is a common issue in multi-sensor systems, and ensures consistent, high-accuracy measurement during every filling cycle.

This servo-controlled gravity feeding scale is widely used in fertilizer and chemical production. It has been applied across a broad range of products, including compound fertilizer, DAP, MAP, urea, oxalic acid, ammonium sulfate, potassium fertilizer, water-soluble fertilizers, and other granular or powder materials that require automated dosing and packaging.

| Machine dimensions (L×W×H) | 950×900×1650mm (including feeding diverter and flow control gate) |

| Applicable materials | Free-flowing powders, granular materials, and micro-granules (gravity feeding without bridging) |

| Weighing range | 20-50kg/bag |

| Capacity | Single scale: 500–800bags/hr Double scale: 800–1200bags/hr (depending on material flowability and bulk density) |

| Accuracy | Static ±0.1% Dynamic ±0.2%, Class X(0.2) |

| Power supply | AC 220V/380V ±5%, 50 Hz±1%, three-phase four-wire |

| Peak power | 3kW |

| Air supply | 0.5–0.7MPa, 140Nm³/h, inlet pipe diameter 1inch |

| Operating temperature | -5°C to 40°C, dew point -40°C |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

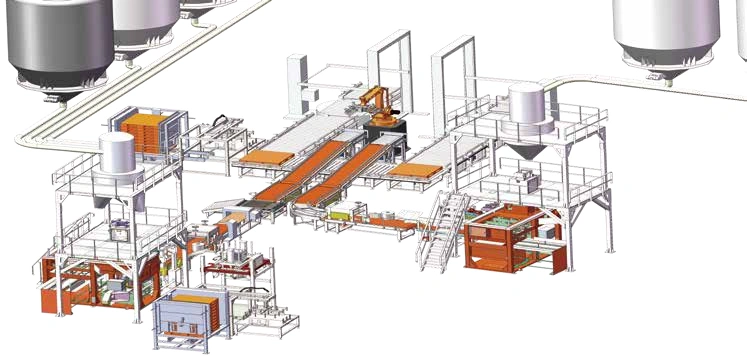

Find the perfect match to complete your bagging line

Learn More