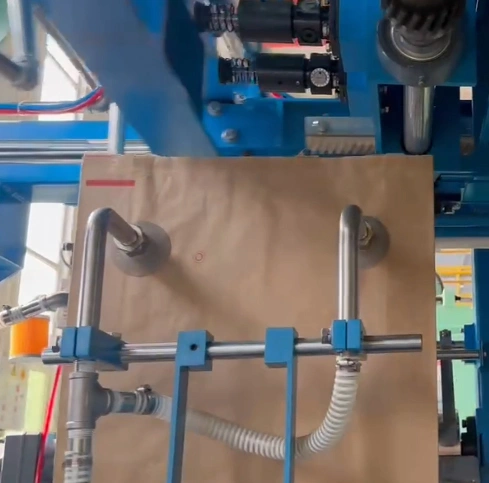

Bag Sewing Machines for Bagging & Palletizing System

- Home

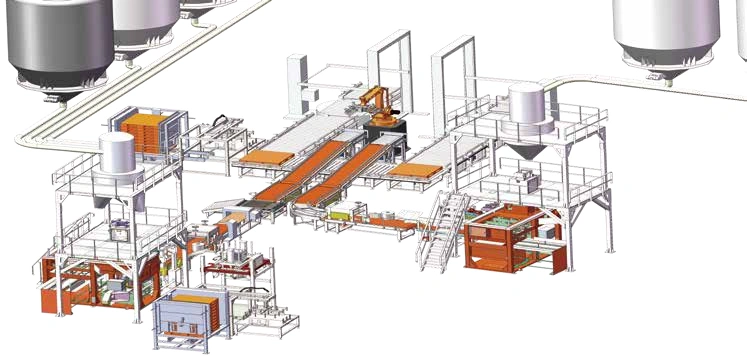

- Bagging and Palletizing System

- Bag Sewing Machines

- Bag Bottom Sewing Machine

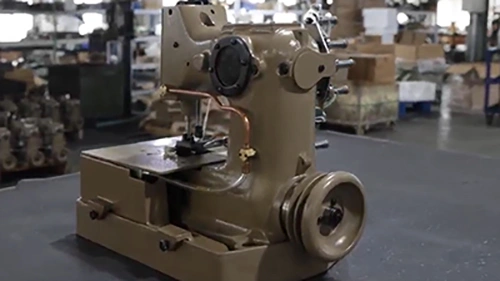

The GKN-2HS and GKN-2LHS are single-needle, two-thread bottom-sewing units designed for closing the bottoms of paper sacks, PP/PE woven packaging, laminated paper bags and other lightweight materials. They use a flat-feed mechanism, and the two versions, right-handed and left-handed, give production lines more flexibility when arranging the sewing station. Their built-in lubrication system keeps the main components oiled during long hours of work, which helps them last longer and reduces how often maintenance is needed.

| Stitch length adjustment | 7–12mm |

| Stitch type | 2-thread chain stitch |

| Needle model | DRX2-#25/26 |

| Machine weight | 35kg |

| Machine dimensions (L×W×H) | 430×220×400mm |

| Lubrication method | automatic lubrication |

| Applicable thread types | polypropylene thread, polyester thread, jute thread |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

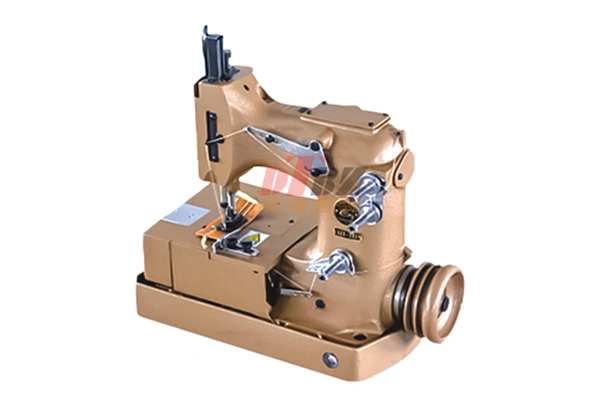

Based on the GKN-2HS/GKN-2LHS design, these bag bottom sewing machines are upgraded with a top-feed mechanism that works together with the lower feed. The combined feeding action gives much better control when sewing thicker or more slippery materials, helping them move steadily through the machine and improving stitch quality.

| Stitch length adjustment | 7–12mm |

| Stitch type | 2-thread chain stitch |

| Needle model | DRX2-#25/26 |

| Machine weight | 35kg |

| Machine dimensions (L×W×H) | 430×220×400mm |

| Lubrication method | automatic lubrication |

| Applicable thread types | polypropylene thread, polyester thread, jute thread |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

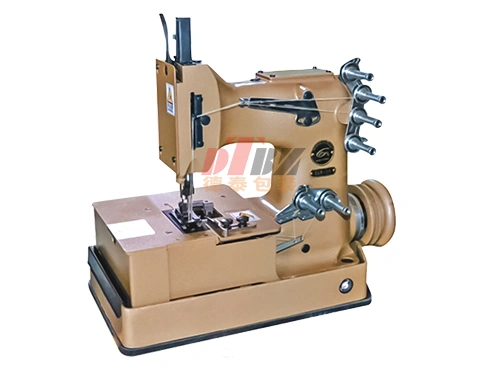

These bag bottom sewing machines use a two-needle, four-thread stitching setup that creates two parallel seams at the same time. The two stitch lines create a stronger hold at the bottom of the bag, making it less likely for the contents to escape while the bag is being handled.

| Stitch length adjustment | 7–11mm |

| Stitch type | 2-thread chain stitch |

| Needle model | UY143GS-200/230 |

| Machine weight | 35kg |

| Machine dimensions (L×W×H) | 430×220×400mm |

| Lubrication method | automatic lubrication |

| Applicable thread types | polypropylene thread, polyester thread, jute thread A, 20/6 or 20/9 synthetic fiber thread or cotton thread |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

These bag bottom sewing machines use a two-needle, four-thread setup that creates two stitch lines at once, giving the bag a stronger and more secure closure. They also use a top-and-bottom feed setup that gives better control over thicker or slippery materials, helping them move at a steady pace and making it easier to keep the stitching neat.

| Stitch length adjustment | 7–11mm |

| Stitch type | 2-thread chain stitch |

| Needle model | UY143GS-200/230 |

| Machine weight | 35kg |

| Machine dimensions (L×W×H) | 430×220×400mm |

| Lubrication method | automatic lubrication |

| Applicable thread types | polypropylene thread, polyester thread, jute thread A, 20/6 or 20/9 synthetic fiber thread or cotton thread |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

Find the perfect match to complete your bagging line

Learn More