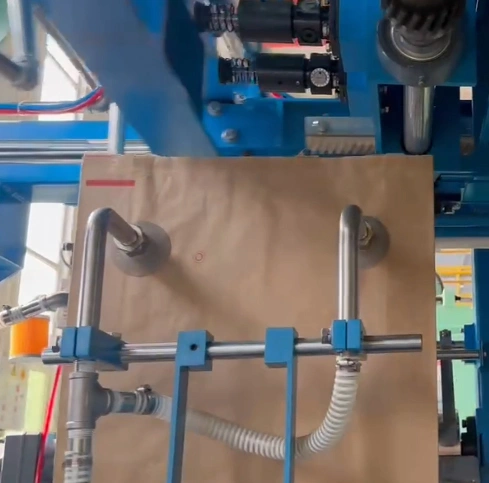

Continuous bag sewing heads with crepe tape cutters are built for packaging lines that run without stopping. As the bag moves forward, the conveyor chain holds the bag's mouth firmly in place so the stitching and crepe tape can be applied in one smooth motion. As the bag moves forward, the conveyor holds it steady enough for the stitches and crepe tape to be applied evenly, even when the line is running fast. The combination of continuous feeding and crepe tape application helps the sealing process run more smoothly for open-mouth bags, especially in plants that handle large volumes and need consistent, uninterrupted operation.

| Feeding method | continuous feed (roller type) |

| Max. sewing speed | 1600rpm |

| Seam thickness | 0–8mm |

| Stitch length | 7.7mm (fixed) |

| Stitch type | 2-thread chain stitch (401), 1 needle |

| Needle model | DN-H29 #26 |

| Thread type | 20/6, 20/9 synthetic fiber thread or cotton thread |

| Thread cutting type | integrated automatic thread cutter |

| Machine weight | 28kg |

| Machine dimensions (L×W×H) | 430×230×380mm |

| GS-7C | pneumatic guillotine crepe tape cutter (for use with automatic heat sealing machine) |

| GS-7A | mechanical thread cutter |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

If you have questions or need further information, our team is here to assist you, feel free to contact us.

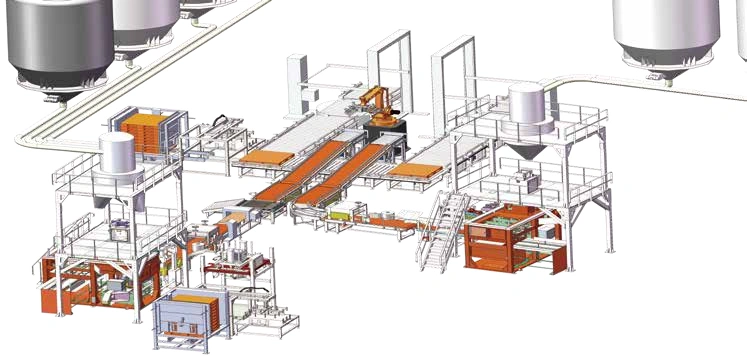

Find the perfect match to complete your bagging line

Learn More